In advanced manufacturing fields such as integrated circuits, MEMS, and optoelectronics, ICP etching technology is widely used in key processes such as deep silicon etching, high depth ratio structure machining, and precision pattern transfer. The stability and uniformity of the etching effect not only depend on the density and energy control of the plasma, but also on a set of highly clean, sealed and reliable gas delivery system. In the core structure of this system, ultra-high-purity stainless steel pipe assemblies and double ferrule joints play an irreplaceable role as the "gas lifeline".

1. ICP etching: put forward the ultimate requirements for the gas system

The ICP etching machine excites high-density plasma through the upper induction coil, and the low electrode bias is used to achieve high anisotropic etching. In order to accurately control the etch depth and sidewall angle at the micro-nanometer scale, the type, ratio, flow rate and purity of the reaction gas must be stable and controllable.

In the actual etching process, common gases include:

• Halogen gases such as Cl₂, SF₆, BCl₃: used for etching of silicon, oxides and other materials;

• O₂: oxidizing or ashing agent;

• Ar, He: plasma stabilizer or diluted gas;

• Corrosive by-products: need to be extracted by the vacuum system in time.

Any tiny gas contamination, leakage, or flow fluctuations can lead to process failures such as uneven etching, sidewall collapse, and particulate contamination. Therefore, the gas passage system should not only be accurate, but also extremely clean, zero leakage, corrosion resistance, stable and reliable, which is the core value of ultra-high purity steel pipe assembly.

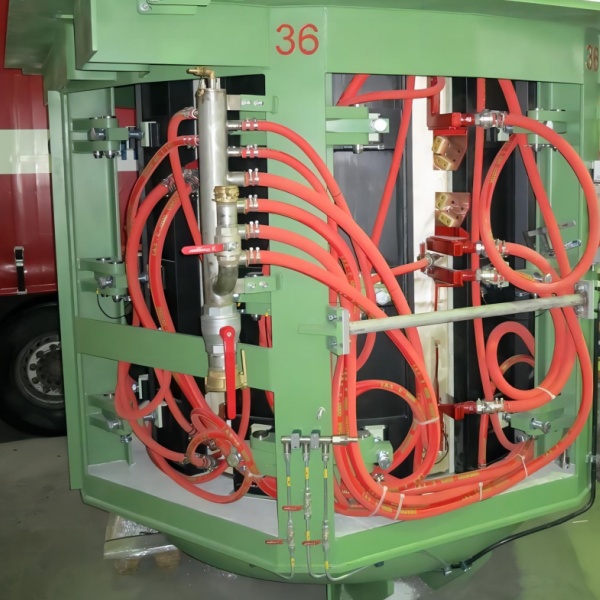

2. Ultra-high purity steel pipe assembly composition and technical highlights

✅ Structural composition:

• 316L seamless stainless steel pipe (EP grade): Electropolished inner wall treatment, surface roughness Ra<0.2μm to prevent particle adhesion and precipitation;

• Double ferrule stainless steel joint: metal seal structure, resistant to high temperature, high pressure, high corrosion, to avoid organic pollution;

• Helium air tightness testing: the whole assembly has been detected by helium mass spectrometry for leakage, and the leakage rate is less than 1×10⁻⁹ Pa·m³/s;

• CGA/SEMI standard port: Seamlessly compatible with the world's mainstream semiconductor equipment interfaces.

✅ Technical advantages:

Characteristics Description

Ultra-clean oil-free and impurity-free treatment process that meets the requirements of 6N (99.9999%) gas delivery

High airtightness Metal hard seal design, zero leakage operation, suitable for high vacuum systems

High reliability Factory prefabricated, fast on-site installation, reliable repeated disassembly

Super corrosion resistance Suitable for all mainstream etching gases for long-term stable operation

Support personalized customization Customized structural forms such as bending pipes, threaded interfaces, and flange welded connections can be customized

3. Key applications in ICP etching systems

In ICP equipment, ultra-high purity steel pipe assemblies are mainly used in the following system nodes:

1. Etching the main channel of the reaction gas

Connecting the gas cylinder and the etching reaction chamber to ensure that the high-purity gas is transmitted to the plasma reaction area without loss and pollution is the core guarantee of the quality stability of etching.

2. Before and after MFC mass flow control

Combined with double ferrule fittings to achieve precise and controllable gas flux, assist in the consistent control of process parameters.

3. Vacuum exhaust path

The corrosion-resistant steel pipe assembly is equipped with vacuum valves and cold traps to achieve residual-free extraction of etching by-products, effectively reducing the pollution rate of the vacuum chamber and the frequency of equipment cleaning.

4. Why can't you replace it with a hose?

Industrial hoses can be used in some low-demand systems (e.g. purging, cooling water), but in ICP main air systems, hoses have serious limitations:

• The cleanliness of the inner wall is difficult to meet the standard, and there is a risk of precipitate.

• Prone to aging, air seepage, and pressure deformation after long-term use;

• The connection form has poor air tightness, making it difficult to resist corrosive gases;

• Susceptible to temperature fluctuations, causing flow disturbances. 、

As a result, any hose substitution poses a potential threat to etch stability, and steel tube assemblies are the only industrial-grade solution that can carry high-purity etch gases.

5. Conclusion: From "conveying gas" to "guarding yield"

In today's wafer fabrication yield management, every process has no room for defects. A tiny source of gas leakage or contamination can mean dozens of wafers are scrapped or even equipment is downtime. The ultra-high purity steel pipe assembly is the "lifeline" that silently guards the purity of gas, the stability of equipment and the consistency of products in an invisible place.

Choosing a high-quality ICP etching gas circuit system is not only about choosing a set of accessories, but also about process stability, production safety, and future reproducibility.