Product Categories

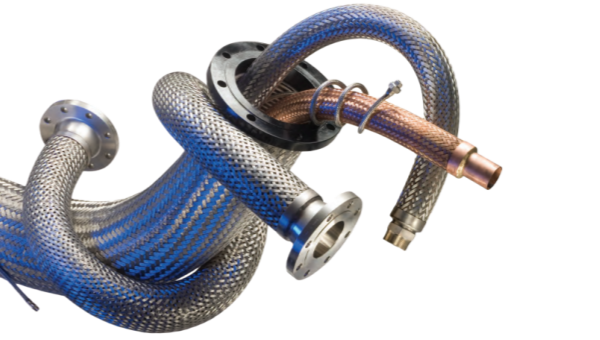

hose

Joint

Hydraulic equipment

Fluid control valves

Rigid tubes

-

Hose fittings

- Metric flat seals

- Metric spherical seals

- Metric 24° Cone Light Series

- Metric 24° cone weight series

- Metric 60° cone seal

- Metric 74° cone seal

- Metric 74° Cone Seal BSPT Inch Cone Pipe Thread

- Pipe thread flat seal

- British pipe thread 60° cone seal

- Pipe threaded spherical seal

- NPT cloth cone pipe thread

- Articulated joints

- Japanese Imperial 60° cone seal

- American JIC 74° cone seal

- US ORFS Flat Seal

- Double-sided core

- Six-layer steel wire stripping inner and outer rubber core

- Detachable hose fittings

- Metric tube sleeve type

-

Adapters

- DIN compression fittings

- Metric threaded O-ring flat seal

- Metric thread 74° cone seal

- Japanese-style British pipe threaded 60° cone seal joint

- British pipe thread 60° cone seal fitting

- Inch cone pipe threaded BSPT fittings

- American tapered pipe threaded NPT fittings

- U.S. 74° tapered thread flare fittings

- U.S. Threaded O-Ring Flat Seal ORFS Fittings

- Standard fittings

- Flange joints

- Twin compression fittings

- Quick couplings

- Swivel joints

- Industrial connectors

- Pressure test fittings

- Fitting accessories

- Application

- Solution

-

Knowledge

- Steam pipe features

- How to choose a carbon-free hose

- Application of insulated tubes in submerged arc furnaces

- Breaker

- Twin tube fitting features

- HB4-4FA-2002 Navigation Connector Features

- The difference between 4SP and 4SH steel wire hose

- Liquid-cooled blind plug quick couplings

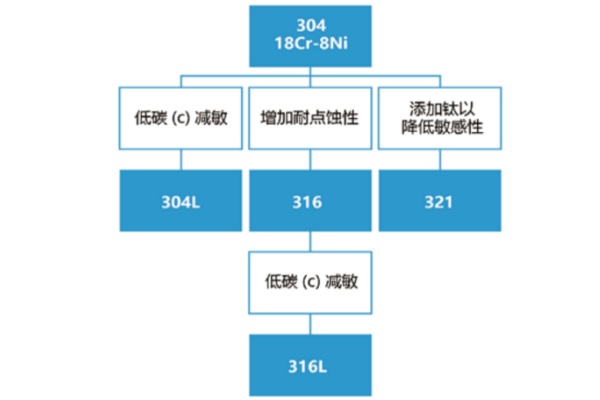

- Ultra-high purity steel pipe assembly

- Dispenser Teflon (PTFE) hose

- Hose assembly installation instructions

- SAE flange core

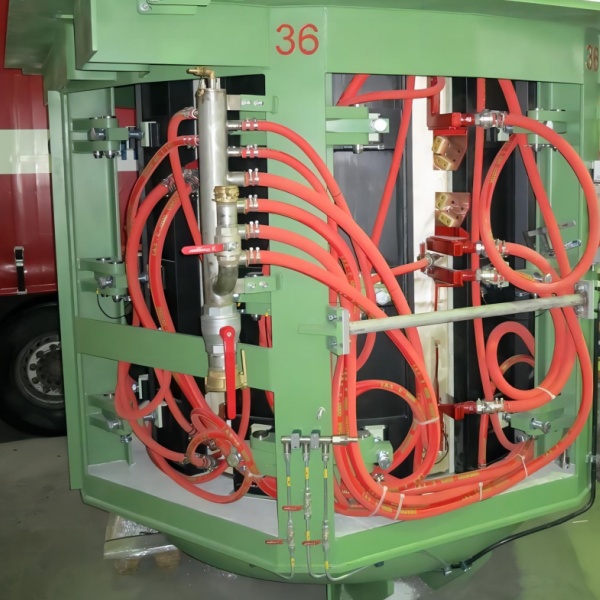

- Carbon Dioxide Fire Suppression System Cylinder Bank

- Hydraulically Driven Dry Piston Compressor

- Introduction to SAE J517 Hydraulic Hose Standard

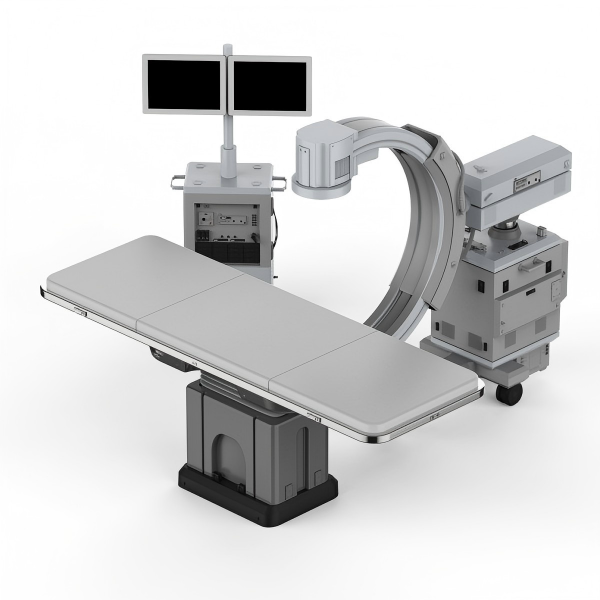

- Series Resonant Medium-Frequency Power Cabinet without Carbon Tube

- About

- Brand Story